Bearing Selection Of Paper Machine

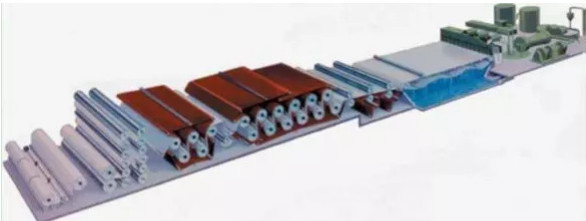

With the increasing demand and demand for paper, mechanical paper has gradually developed. From pulping, modulating, pressing, to calendering, cutting and packaging, the development of science and technology has made a series of papermaking programs complete by machine. Moreover, all kinds of exquisite, practical and environment-friendly paper varieties emerge one after another. However, the processing difficulty of these products is far beyond imagination. The complicated and harsh processing environment is a major challenge to the modern paper industry because of the limited capacity of the key parts of the equipment.

Industrial Bearings Solutions has been designing and supplying bearings for the paper industry for more than 70 years. Whether it is paper machine or pulp line or even forestry saw machine, Industrial Bearings Solutions is well aware of the needs of equipment and provides products of high quality and reliability. To sum up, Industrial Bearings Solutions has seven product types to meet the needs of all kinds of paper-making equipment.

1. Timken high performance centrifugal roller bearings

Self aligning roller bearing is the most commonly used bearing type in paper machine production line. From inside diameter 25mm to 1500mm, Industrial Bearings Solutions provides high performance self-aligning roller bearings with various steel and copper cage.

2 Timken ADAPT bearing

The ADAPT bearing, which is mainly used for dryer equipment, is an innovative product of The Timken Company. It combines the excellent axial floating ability of cylindrical roller bearing and eccentric capability of spherical roller bearing. At the same time, it has the characteristics of simple installation, strong interchangeability and easy lubrication. Experiments show that the life of the ADAPT bearing is 30% longer than that of the ordinary product, the rated load is increased by 3.5-7%, the running temperature and the friction torque are reduced by 5-10%.

3 Timken bearing seat bearing unit

On the pulp line, from the peeling machine to the slicer, from the conveying system to the slurry screen, the various seat bearing units of the The Timken Company are very clear.

Avoiding unplanned downtime is the key to ensuring high productivity and low cost. The papermaking enterprises once encountered problems of frequent shutdowns and replacement of bearings due to the failure of bearing performance to meet the operating conditions of paper machines. Industrial Bearings Solutions analyzed the reasons for the customer and recommended the Industrial Bearings Solutions dedicated paper machine roller bearing. The project leader and service engineer were closely related to the customers during the installation and maintenance stage, and finally ensured the smooth operation of the equipment.