Measurement Of Axial Clearance Of Double Row Tapered Roller Bearings

The axial clearance of double row tapered roller bearings has great influence on the rotation accuracy, bearing capacity and service life of bearings. Therefore, the Industrial Bearings Solutions control is very important for the axial clearance of double row tapered roller bearings, especially in the rolling of seamless steel tubes, the technological accuracy of the axial clearance of double row tapered bearings on the steel pipe products is very important. It plays a vital role. Industrial Bearings Solutions introduces a simple measurement method.

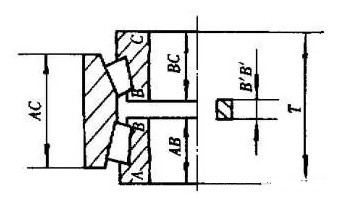

As shown in Figure 1, when the spacer width B "B" is greater than two inner ring spacing BB, the spacer will be placed between BB, resulting in clearance between the roller and the back side of the raceway. The clearance in the axial direction is the axial clearance. The size of the axial clearance depends on the difference between BB and B "B", that is =B "B" -BB, which is stipulated by the technical conditions, so as long as it is true. The size of the clearance can be obtained by setting the size of BB.

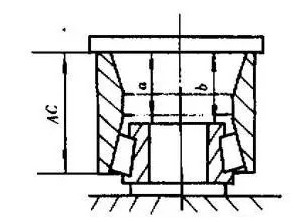

Measurement method: place the outer ring and inner ring assembly as shown in Figure 2, add the load specified on the end of the outer ring end, and turn the outer ring with the hand. When the correct contact between the roller and the raceway and the flange is carried out, the load is downloaded. The size a is measured, then the end face of the same outer ring is turned over and the other inner ring assembly is shown in Figure 1. It is shown that the size B is measured according to the above method. When measuring a and B, measure 90 points per interval, and take the arithmetic mean of 4 actual dimensions. The clearance is: the width of the AC+ spacer - (a+b) [AC for outer ring height].